Standard construction can be slow, costly, and inefficient. Machines might do it better.

Before Jason Ballard became an entrepreneur, he considered becoming a priest. His speech is still peppered with the idiom of faith—wicked, angels, sacred—and, when he latches on to a subject he cares about, he assumes a rousing, propulsive cadence. These days, the topic he is most evangelical about is our broken housing system. “What we’re doing is not working,” Ballard told me last spring. “There are far too many homeless people. Working-class people can’t afford basic housing in regular old American cities. Construction’s too wasteful. Houses aren’t energy-efficient enough. At the suburb scale, it’s dystopian, almost, what we’re getting, right? We’re supposed to be the most advanced version of humanity that’s ever existed and we can’t even meet this basic need properly. And that means the housing of our future can’t—not shouldn’t, but can’t—be like the housing we have now.”

In 2017, Ballard co-founded Icon, a construction startup focussed on what he believes to be a solution to the housing crisis: 3-D-printed construction, a largely automated method that creates buildings layer by layer, typically with cement-based material. The company has offices in the Yard, a mixed-use development in a formerly industrial area of Austin, Texas. The Yard is currently home to a sake company, a winery, a brewery, a canned-cocktail company, a hard-seltzer manufacturer, a whiskey distillery, and a Tesla dealership. On the morning I visited, the air was thick with the sweet-sour smell of fermentation.

Amid supply-chain issues, labor shortages, and the rising cost of construction materials, there has been a surge of interest in novel ways of building, and Icon has grown accordingly. Five years ago, fewer than ten people worked at the company; now it employs more than four hundred. Ballard, who is forty and has bright eyes and a guileless, open face, met me in a narrow conference room. Placards on the wall read “Courage,” “Ambition,” and “Velocity.” He wore a black Patagonia jacket embroidered with the company’s name and, as he often does, a white cowboy hat.

So far, 3-D-printed construction has generated more headlines than buildings. In the past few years, companies have announced the first 3-D-printed house in Florida, “the first two story house printed on site in Europe,” and the first market-rate 3-D-printed house sold in the United States. Until last year, Icon, one of the biggest and best-funded companies in the field, had printed fewer than two dozen houses, most of them essentially test cases. But, when I met Ballard, the company had recently announced a partnership with Lennar, the second-largest home-builder in the United States, to print a hundred houses in a development outside Austin. A lot was riding on the project, which would be a test of whether the technology was ready for the mainstream. “We almost won’t get out of bed for less than a hundred homes anymore,” Ballard told me. “This is a problem at scale, and so we need to be working at scale.”

In Austin, where the median rent has risen forty-five per cent in the past year, the tech industry is usually considered a driver of the housing crisis, rather than its solution. “In short order, like Silicon Valley, it could result in people having to make career decisions and say, ‘I can’t live there, I can’t afford it,’ ” Henry Cisneros, a former Secretary of Housing and Urban Development and mayor of San Antonio, said at a panel on housing affordability at South by Southwest last year. The next day, Ballard, one of the conference’s featured speakers, made a more techno-utopian pitch. “What if we could build houses that work twice as good in half the time at half the price? What kind of problems could we solve? What kind of opportunities would open up before us?” he asked. “Humans are amazing, life is a miracle, and we can do this.”

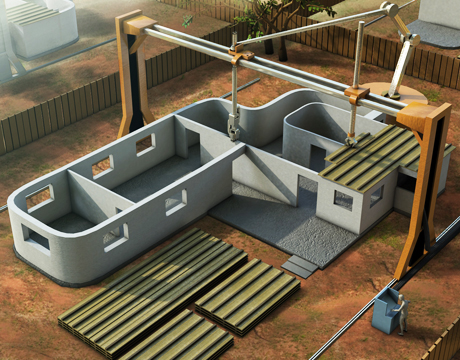

When I heard that you could 3-D-print a building, I imagined something akin to a “Star Trek” replicator—a machine that would whir briefly and then spit out a fully formed house. The actual process is messier and more laborious, and, at the moment, it is largely used to construct walls, while conventional methods are used for foundations, floors, roofs, and finishes. But walls are among the most costly and labor-intensive aspects of home-building, and, in the majority of newly built U.S. homes, they’re likely to be made out of drywall panels mounted on wooden frames. Though drywall is easy to produce and relatively inexpensive, it takes a while to install, is not particularly sturdy, and is susceptible to mold. 3-D-printing advocates argue that rethinking our walls is a step toward building cheaper, more resilient houses.

Before my visit to the Yard, I spent an afternoon watching printers in action on YouTube. The videos are hypnotically pleasurable, providing the lulling satisfaction of seeing a machine do its job perfectly. A nozzle sweeps back and forth, extruding a concrete-like substance in ascending inch-thick layers, following a blueprint fed to it by a software system. A printer can create the shell of a simple building in as little as twenty-four hours, although real-world conditions (rain, cold temperatures, operator error) slow the process. In the past two years, as Icon has expanded, its fleet of printers, called Vulcans, has printed military barracks, disaster-resilient houses, a luxury residence, and, at the Johnson Space Center, in Houston, a full-sized simulation of a Martian habitat, for nasa. Other 3-D-printing companies have produced an apartment building, a houseboat in the Czech Republic, and a house for Habitat for Humanity. Dubai has pledged that, by 2030, a quarter of its new construction will be printed.

At the Yard, two employees kept watch as a Vulcan moved along a track, its nozzle depositing lines of gray LavaCrete, Icon’s proprietary cement mixture. It had the texture of gritty toothpaste and smelled like cookie batter. The Vulcan was attached, via a thick hose, to Magma, a sophisticated version of a cement mixer, which blends LavaCrete and various additives. In the traditional construction world, concrete is considered a material with a high tolerance for imprecision, but in 3-D printing it must be liquid enough to move smoothly through the printer but then solidify rapidly, in order to receive the next layer by the time the printer head returns. The Magma’s software takes weather measurements (temperature, pressure, humidity) every fifteen minutes and adjusts the mixture—adding a superplasticizer if it’s cold, or a retarder if it’s hot. Ballard pointed out the Vulcan that had printed the Martian habitat; it was back at the factory to be serviced. “That’s also the one that printed the house you’re going to stay in tonight,” he said.

Ballard speaks quickly and with such bright conviction that I left my conversations with him briefly convinced that the world was full of untapped potential. He grew up in Orange, the easternmost city in Texas, a humid, hurricane-battered place on the border of Louisiana. “You could throw a football from my front yard into the Gulf of Mexico,” he told me. “Except it’s like a swamp right there, not a beach.” The Gulf Coast was thrillingly biodiverse, populated by flying squirrels, roseate spoonbills, and alligator gar. It was also crowded with petrochemical plants. “There are signs all over town, like, ‘Do not eat the fish in this water,’ ” Ballard said. “Seeing the desecration—it just makes you ask bigger questions than the typical eighth grader is asking.” In 2006, he became the first person in his immediate family to graduate from college, earning a degree in conservation biology from Texas A. & M. Two years later, Hurricane Ike flooded his childhood home with six feet of water. Ballard spent weeks ripping sodden drywall and insulation from the damaged structure. “And, sure enough, they rebuilt it with drywall,” he said. Nine years later, floods from Hurricane Harvey damaged eighty-five per cent of the homes in Orange, according to the mayor. Ballard’s parents, defeated, moved inland. The experience left Ballard with a strong dislike for drywall, a material that he sometimes seems to take as a personal affront. “If I offered a one-million-dollar prize to people in this room to invent a less resilient, less durable, less healthy, less sustainable material than drywall, nobody would win the prize,” he said at his South by Southwest talk. “We literally can’t think of a way to do it worse.”

After college, Ballard and his now wife, Jenny, moved to Boulder, Colorado, where he took a job at a homeless shelter and got to know some people who worked in sustainable construction. His new friends preached about the evils of standard building methods—how much energy they consume, how much landfill waste is produced. “I was, like, Jesus, I don’t need to be a field biologist, I need to be working in buildings,” Ballard said. He and Jenny moved to Austin to run TreeHouse, a sustainable-building-supply company he co-founded with a college friend, Evan Loomis. TreeHouse positioned itself as a green alternative to Home Depot, selling pure-wool carpets, smart thermostats, and cabinets made from sustainable lumber. In a hippie town just starting to swell with tech money, the company proved popular. But within a few years Ballard came to believe that the kinds of building intervention he was selling were not sufficiently transformative. “It was all accepting the current paradigm—this is the way we’re going to build houses, let’s just make them a little better,” he said.

One day, Ballard told Jenny that his heart wasn’t in TreeHouse anymore. “ ‘Guilt’ isn’t the right word,” he told me. “But I’m losing faith that the world will be different because of this business. Something much more radical has to happen.”

After the Second World War, the housing market was unable to keep up with the demand produced by returning soldiers and their new families, a situation so extreme that President Truman appointed an official housing expediter. Subsidized by federal funding, entrepreneurs experimented with new ways to mass-produce houses. It was a boom time for visionaries, who dreamed of new forms, new materials, new ways of living.

Buckminster Fuller had once copied a pronouncement by Le Corbusier into his journal: “The problem of the house has not yet been stated.” After Fuller’s first foray into industrialized construction, the Dymaxion House, failed, he turned to a new form, the geodesic dome. Carl Strandlund, a Midwestern inventor, claimed that his Lustron homes, one-story houses made of prefabricated enamelled-steel panels, weren’t just an improvement on existing structures but “a new way of life.” Around the same time, an entrepreneur named William Levitt applied the principles of the assembly line to home-building, first on Long Island and later in Pennsylvania. Relying in large part on drywall for its construction, a standard tract house in Levittown cost a little less than eight thousand dollars, the equivalent of about a hundred thousand dollars today. (The promise of accessible homeownership was not open to everyone. Robert Mereday, whose company delivered drywall to Levittown, didn’t even bother to put in an application on one of the new houses. “It was generally known that Black people couldn’t buy into the development,” his son later recalled. “When you grow up and live in a place, you know what the rules are.”)

Strandlund eventually filed for bankruptcy, and Fuller never managed to mass-produce residential domes, but Levitt’s influence on the built environment persists. Today, new-home construction is dominated by production builders who, like Levitt, buy tracts of land and erect houses by the thousands, keeping costs low by building at scale. Prioritizing operational efficiencies, Ballard believes, has led to what he calls the housing “doom loop”: “When you use lower-quality materials, and lower-quality labor, and you recycle designs, and you make the lots smaller, the outcome isn’t that nice. Then cities respond by layering on a bunch of new regulations. And then the builders have to cut even more corners. That means the quality of the homes goes down again. And now the city comes back with more regulation. And this is the doom loop that’s gotten us to where we are today.”

When I put Ballard’s doom-loop theory to Jenny Schuetz, a senior fellow at the Brookings Institution who specializes in housing policy, she pointed out that our political system is structured such that current residents can, and often do, stymie efforts to build more housing. “People don’t want more neighbors, more traffic, and more congestion on the roads, more kids in schools,” she said. “And, when you get into multifamily housing, there’s a lot of pushback against renters, often via not very thinly veiled racist and classist remarks about the kinds of people who rent homes.” She also noted that the construction industry never fully recovered from the 2008 recession: fewer new homes were built in the U.S. in the following ten years than in any decade since the nineteen-sixties, even as the population continued to grow. According to the Federal National Mortgage Association, the U.S. is short some four million housing units, a deficit that’s worse for low-income households.

In 2016, while Ballard was still working at TreeHouse, he began meeting with friends to talk about alternative construction methods: zip panels, sip panels, shipping-container houses, prefab houses, houses grown out of fungus. 3-D printing quickly emerged as the most alluring option. It used technology to automate and speed up building, but it also allowed much more design freedom than techniques that relied on prefabricated materials. A printer could erect thick walls with relative ease, and that made the resulting buildings more energy-efficient and structurally sound. Concrete wasn’t particularly vulnerable to mold, and the printing process created much less waste than standard building did. Although making concrete is carbon-intensive—cement manufacturing is responsible for some eight per cent of global CO2 emissions—Ballard came to believe that it was his best option. “If you replace all that concrete with lumber, replace it with plastics, it’s much more ecologically devastating,” he said. “Wood is lovely, but it’s a conductor of heat, so you spend all this money and time insulating it,” he went on. “It wants to rot, it wants to catch fire, it wants to be termite food. There are a lot of first-principles reasons that, if an alien showed up and you asked it what would be the better building material, the concrete or the wood, it’s for sure the concrete. We’ve got bridges that stand in salt water for a hundred years—they’re made of concrete. We’ve got concrete domes in Rome that have been there for a thousand years.”

The idea of “printing” a building with concrete originated with Behrokh Khoshnevis, an engineering professor at the University of Southern California. In the nineteen-nineties and early two-thousands, Khoshnevis, an early proponent of small-scale 3-D printing with plastics and metals, began experimenting with using the technology to make much bigger objects—industrial parts, at first, and then, eventually, buildings. His printer consisted of a nozzle attached to a movable gantry crane. The work was dirtier and more difficult than many of his graduate students liked, but Khoshnevis came to believe that the technology had the possibility to transform the world. In 2012, he gave a talk at a tedx conference in Medellín, Colombia. “Anybody who has built a house knows the problem with the construction process. The solution is nothing other than automation,” he said. “We’re talking about the technology that can build custom-designed homes onsite, entirely by the machine, in one day.” Two years later, he printed the shell of a prototype house in less than twenty-four hours, an event that was widely covered by the media.

Ballard, intrigued by the potential of 3-D printing, reached out to Andrew Logan, a college friend who was working as an architect in Austin. “I was the first available person he knew that might be interested in drawing something harebrained,” Logan told me. “There wasn’t a grand ambition that there was going to be a business behind this. It was just, like, ‘Let’s see if we can 3-D-print a building. Let’s see if we can pull this off.’ ”

Their first attempt took place in a friend’s back yard, on Chicon Street in East Austin, in 2018. Ballard and some friends churned batches of concrete in a standing mixer, then poured them into a prototype printer with a bucket. When the mixture started to clog, Ballard’s wife, Jenny, suggested using a window screen to sift the clumps. The three-hundred-and-fifty-square-foot structure was completed hours before South by Southwest’s opening day. An article reported that the house had been printed in a day, at a cost of four thousand dollars. It had taken more time and money to complete the structure—that figure applied only to the wall system—but news of the cheap, fast house circulated widely. “We kind of won South By that year,” Ballard said. “It just caught fire. And that unfortunate headline about the four-thousand-dollar houses probably helped us catch fire.” Icon, which he founded with Loomis and Alex Le Roux, did its seed round of funding later that year. Ballard began to talk about printing homes by the hundreds, then the thousands, then the millions; he’d finally found a project appropriately sized to his ambitions. Four years after the Chicon-house experiment, Icon was valued at nearly two billion dollars.

Ballard’s grand statements about the future of 3-D printing haven’t endeared him to everyone in the industry. Philip Lund-Nielsen is a co-founder of cobod International, a 3-D-printing construction company headquartered in Copenhagen. “Let me just put it this way,” he said. “There’s a lot of U.S. companies that are very, very ambitious, or optimistic, in their marketing materials.” Too much hype can be harmful in the long term, Lund-Nielsen said: “You just blow up the potential where the expectations don’t meet the reality of the technology.” He told me it’s “very likely” that 3-D-printed construction will eventually be a significantly more efficient way to build. “But maybe a few years down the line,” he said. When I posed this criticism to Ballard, he scoffed. “I haven’t even started raising expectations,” he said. “They’re going to be terrified of what we’re about to do.”

Eric Feder, the president of LenX, Lennar’s innovation arm, told me that his job involves anticipating disruption: if the production builders were Blockbuster, then who was Netflix? In 2019, Feder travelled to Austin to meet with Ballard, who made a strong first impression—cowboy boots, cowboy hat, sophisticated understanding of materials science. Feder came away from the meeting convinced that Ballard had the kind of founder vibe—a charisma rooted in relentless energy—that, though familiar in Silicon Valley, was uncommon in the construction industry. He compared Icon to Tesla, and Ballard to Elon Musk. “What they’re doing doesn’t appeal to everyone,” he said. “But it’s new and cool and sexy. And there’s a massive addressable market. You can’t help but say to yourself, ‘Wow.’ ”

Stuart Miller, Lennar’s executive chairman, told me that he was initially “somewhat dismissive” of 3-D-printed construction. “Innovation is an expensive exercise with unproven returns,” he said. “Look, we go to work every day, we make sure the trains run on time, we build our business with the known methods, the known programs, the known economics.” But, by the fall of 2020, the known economics weren’t working as well as they used to. The supply-chain crunch was at its worst, and Lennar was having trouble finding adequate supplies of lumber and engineered wood. In Austin, which became the country’s second-fastest-growing city during the pandemic, the problems were particularly acute. The median home price rose a hundred thousand dollars between 2020 and 2021, and Lennar struggled to build enough houses to meet the demand. The two companies agreed to what was for Lennar a small experiment and for Icon a high-stakes chance to prove itself: printing a hundred houses, an entire suburban neighborhood.

Ballard believed that one reason previous attempts to commercialize 3-D-printed construction had failed was a lack of attention to aesthetics. He got frustrated when he saw 3-D-printed houses that looked just like their traditionally built equivalents. It was as easy to print a curved line as a straight one, so why force the material into right angles? He liked to scroll through the sinuous imaginary structures people made using such A.I. art programs as Dall-E and Midjourney. “The world doesn’t want boxes,” he told me. “That’s not what’s in the human heart.”

In 2019, the Danish architect Bjarke Ingels, who was speaking at South by Southwest, saw the Chicon house and arranged a meeting with Ballard. The two men hit it off right away. “His cowboy hat! And his Texas accent!” Ingels recalled. Ingels’s outsized tendencies aligned with Ballard’s. “I love Darwin’s idea of evolution so much that I called my son Darwin,” Ingels said. “And Jason called his twins Apollo and Artemis.”

Ingels played around with designing a house that could be entirely printed, including the roof. “You get forms that look incredibly fresh,” he told me. “These mixes of squares and domes, these ‘squomes.’ ” They reminded him of the domed houses of Puglia, in Italy, which are built out of limestone boulders, and of Luke Skywalker’s hut on Tatooine, but they also looked entirely themselves. Ingels’s firm, Bjarke Ingels Group, signed on to design the houses Icon was building for Lennar.

Icon’s first foray into the expressive potential of 3-D-printed architecture was House Zero, a two-thousand-square-foot luxury home designed by the Texas architects Lake Flato. I met Ballard at the house last February, shortly after it was completed. Ballard had asked Lake Flato to design a structure that would show off the distinctive potential of printed architecture. The hallways were undulating and the rooms had curved edges. The ribbed concrete walls were left unpainted. There is not a square inch of drywall in the entire structure. “That costs money,” Ballard admitted. “But this house is designed to make a point, and part of that point is psychological. You’re so used to having to have Sheetrock, to having to have straight walls.”

I was one of the first people to spend the night in House Zero, and the Icon team seemed slightly reluctant to release the place into my care. “Let us know if there are any issues at all,” a P.R. representative said twice. After they left, I sat alone in the nearly circular dining room. I had expected a 3-D-printed house to have the industrial precision of an architectural rendering come to life, but the effect was unexpectedly cozy, something like being inside a coil pot. I thought of what Logan, the architect, had described as the “wabi-sabi” character of a printed wall. “It’s not an iPhone, with a one-sixteenth level of detail,” he said. “From, like, a construction-honesty standpoint, it’s cool. You understand what you’re inhabiting. With drywall, you’re just looking at a smooth surface that tells you nothing about how it was actually assembled, versus a plaster wall, where you see how the workman’s hands rubbed in a circular pattern. You get the same thing with 3-D printing, it’s just that a robot did it.”

Tim Shea is the first person in the U.S. to live full time in a 3-D-printed house, which Icon built in 2019, on the outskirts of Austin, as part of the Community First! Village, a master-planned neighborhood of tiny homes for formerly homeless people. I visited him there on a frigid day. The concrete walls were painted white, and a cat drowsed on the bed. “I keep the room hotter than I like it, just because I worry she’s going to be cold,” Shea said.

Shea, who is in his seventies, told me that he’d become addicted to heroin as a young man. “I took little breaks—I got married, had a couple kids, worked for G.M. and some straight places like that, but I never got it out of my system,” he said. Over the years, he was arrested a handful of times on drug charges. By the time he was in his early sixties, he was clean, but his arthritis was so bad that he had both knees replaced and could no longer handle a job involving manual labor. He spent years living in rooming houses, but, as property values in Austin crept upward, those arrangements were growing difficult to find. Between rising rents and his criminal record, he told me, “there was just nowhere clean and decent to live.” He began sleeping in parking lots, and life on the streets compounded his problems. “When you’re just walking and walking and walking all day, and it’s a hundred degrees out, you start getting delusional,” he said.

Tiny-home compounds like Shea’s—which was a project of the nonprofit Mobile Loaves & Fishes—have cropped up all over the country, in an attempt to address the growing issue of homelessness. (In 2019, the Austin City Council removed a long-standing ban on public camping in an attempt to decriminalize homelessness; two years later, the city’s voters elected to reinstate it.) Icon has also printed houses in Mexico for New Story, a nonprofit combatting homelessness. But the need is too large to be addressed by nonprofits alone. “There’s not enough philanthropy in the world,” Sarah Lee, New Story’s chief operating officer, told me. “You’ve got to get developers incentivized to go down-market, to do it in a way that’s responsible.” But Schuetz, of the Brookings Institution, is skeptical that new technologies will get us there. “People are trying to come up with technical fixes to what is fundamentally a political problem. There are a lot of deep-seated reasons why people oppose housing well before you get to, How are we going to physically construct this thing? And there’s no technology that’s going to fix the politics.”

Ballard has talked about 3-D-printed construction offering “a quantum leap in affordability.” So far, though, the savings have not been so dramatic. Icon estimates that House Zero cost at least ten per cent less than it would have if it had been built conventionally. The houses that Icon printed for New Story were “on the more expensive end,” Lee said, although the process was much faster than other building methods the nonprofit has used—“easily half the time.” Design elements that tend to drive up costs—thick walls, curved edges, floor-to-ceiling windows—can be cheaper to build with 3-D printing. But other relatively straightforward tasks, such as installing a standard window, can be surprisingly pricey. “You’re having to buy this product off the shelf that was designed to fit into wood and kind of jerry-rig it into concrete,” Ballard said. As yet, 3-D-printed construction is mostly used to create single-family structures, not the more dense housing that most experts say we’ll need to address the gap in supply.

The path that Ballard proposes to take to improve the supply and affordability of housing is circuitous. “It’s funny,” he told me. “It might just turn out that some of the answers to our problems on Earth are on the moon.”

My trip to Icon’s headquarters happened to coincide with a visit by a team from nasa. Ballard introduced me to one of the visiting scientists, a woman with glasses and a focussed air. I asked her in passing if she thought we’d have a moon base in my lifetime. “Absolutely,” she said, with surprising force. Afterward, Ballard told me that the woman was Jennifer Edmunson, nasa’s leading expert on moon dust. (Edmunson clarified that her expertise is in “lunar regolith simulants.”)

3-D printing has emerged as a promising way to build the landing pads, roads, and other infrastructure we’d need to expand human habitation beyond Earth. Rather than rocketing construction materials into space, we could use 3-D printers to build structures with lunar materials. (The lack of available water on the moon poses additional problems, such as how to make the dust liquid enough to print; the best solution so far seems to involve melting it with lasers.) nasa recently awarded Icon a fifty-seven-million-dollar contract to develop lunar-construction technology. The company’s Web site now has pages dedicated to both Residential Construction and Off-World Construction.

It is difficult to build utopian housing in a non-utopian world. Many of the mid-century attempts at reinventing housing on an industrial scale eventually foundered. Building codes are highly localized, posing a challenge for mass production—a design that works in one place might not be permitted in another. And, though people may love hearing about new kinds of houses, they don’t always want to inhabit them. Buckminster Fuller’s own geodesic house leaked, and his wife wasn’t sure how to hang pictures on the slanted walls.

Behrokh Khoshnevis, the engineer who pioneered 3-D-printed construction, has become jaded about the technology’s potential. “All the hype is not warranted,” he told me. When I asked him about his tedx talk from a decade ago, he sounded wistful. “I was very optimistic,” he said. Khoshnevis never succeeded at taking the technology mainstream. “I’m glad I started kind of a movement,” he said. “And I’d like it to succeed. I think it will, but it’s going to take time, and it’s not going to be at the scale I envisioned originally—it’s not going to be most buildings.” He’d come to believe that the construction industry was not ready for a total disruption. The experience seemed to have made him philosophical. “The best thing is reality, knowing the reality, not living in fantasy,” he said. “Understanding reality is as good of an achievement as materializing the fantasy that you have.”

At the end of November, I visited Wolf Ranch, the development where Icon is printing a hundred houses for Lennar. The plot is in Georgetown, a former farming community that’s being absorbed by the northward sprawl of Austin. It was the first time I’d seen Vulcans at work outside. Their nozzles glided over concrete slabs, tracing the outlines of rooms.

Ballard strode across the development to greet me. We walked along the neighborhood’s curving streets, toward an unfinished house, whose walls were about five feet high. A worker in a hard hat and a fluorescent vest bent over an iPad, which he used to adjust the nozzle’s speed. (Ballard is often asked whether 3-D printing will destroy jobs in construction. His standard response is that the industry is suffering from a serious labor shortage. “If you know construction workers standing around, looking for work, can you please send them to Texas?” he said.) Apart from the churn of a Magma mixing LavaCrete and the occasional beeping of a reversing delivery truck, the site was notably quiet.

The project was several months behind schedule. The Vulcans had, for the most part, performed as expected; the challenge was everything else. It had been a cold and rainy fall, suboptimal printing weather, and then there were all the operational difficulties—pouring slabs, coördinating deliveries, waiting for a delayed shipment of power transformers. “It’s no joke, it’s like a military deployment,” Ballard said. “Mistakes are tens of thousands of dollars per day.” The initial houses had taken between three and four weeks to print, and Ballard was eager to speed things up. “I would love to see us go, like, blazing-saddles fast,” he said. He planned to petition the city of Georgetown to get permission to print twenty-four hours a day.

When they’re complete, the Wolf Ranch houses will range from fifteen hundred to twenty-one hundred square feet and come equipped with solar panels on their pitched metal roofs. Lennar anticipates that their prices will start in the mid-four-hundred-thousand-dollar range. The eight different floor plans were designed by the Bjarke Ingels Group. The houses had some of the distinct characteristics of 3-D-printed architecture—curved corners, ribbed walls—but there were no squomes in sight. “They are still the children of rectangular thinking,” Ballard said. “Lennar wanted to keep it one standard deviation from normal, whereas Bjarke wanted to go, like, three. We’ll take it one step at a time.”

The development will be a neighborhood of single-family ranch-style houses, each with a two-car garage and a green patch of lawn. The future always looks more like the present than I expect it to. I said something like this to Ballard, and he briefly bristled. “If an entirely solar-powered community, made of resilient materials, designed by a world-class architect, at working-class prices, doesn’t feel like a paradigm shift—we’ll try harder, but I’m pretty proud of it.”

Then he conceded the point. “What you’re feeling I also feel,” he said. More radical things were in the works, he assured me. A new generation of printers, expanded capabilities, dramatically increased speeds. Printing homes by the thousands, designing communities, reimagining the built world. In the meantime, he’d applied to be in nasa’s next astronaut crew. He’d been rejected on this round, but he planned to try again. You never know what might happen next.

Source: The New Yorker

Recent Comments